J'ai trouvé un document intéressant sur le site rockauto.

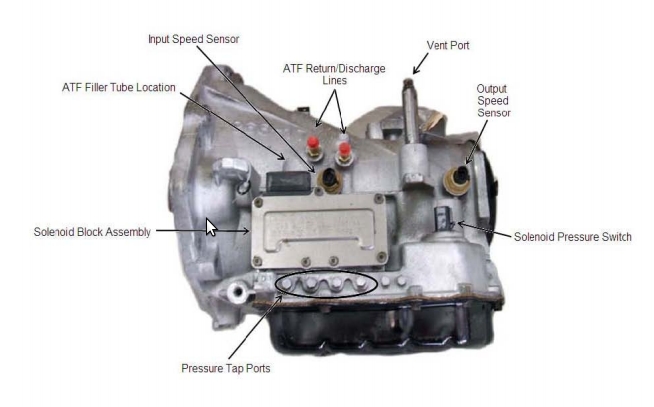

Si on regarde les photos ci dessous.

Ma fuite sort au dessus de l 'angle du carter de boite à gauche où c'est écrit port de test pression; donc ca peut être les allé et erreurs de l échangeur qui couleraient sur le bloc, Ou le bloc lui même; je vais donc vérifier toute la façade de la photo et voir si c est seulement le bloc ou si ca vient d 'au dessus. si ca vient pas d 'au dessus obligé de remplacer le bloc et son joint...

IMPORTANT INSTALLATION NOTICE

The most failure prone component on the Chrysler A604 front wheel drive four speed automatic

transaxle would probably be the electronic shift solenoid block assembly mounted on the

outside of the transaxle case. This solenoid block assembly either experiences failure through

leakage of the unit, electrical failure, corrosion, and/or normal wear.

Replacement of the shift solenoid block assembly can be expensive especially if it was replaced

because of leakage that may have been misdiagnosed. The most aggravating and most difficult

diagnostics technicians may encounter would be determining the main source of a leak.

ATF that is confined and under pressure inside the transmission assembly will find its path to

leak out from either a worn seal, o’ring, gasket, transmission lines or a hairline crack on the

transmission case.

We all know that when fluid leaks out, it usually runs from top to bottom. Since the solenoid

assembly box is located at the lower side of the transmission assembly and is surrounded by

many components that are prone to leaking, it is important to inspect the other components first

before blaming the leak on the solenoid assembly block. Furthermore, by adding ATF through

the filler tube during maintenance, any ATF that may have spilled will easily run down towards

the solenoid block assembly leading to misdiagnosing a solenoid leak.

A simple procedure to acurately pinpoint the source of a leak is through a use of a special dye

and a black lamp. The dye will appear, usually yellow in color, on the fluid leak when the light of

the black lamp is shined on it.

Below is an illustration of the Chrysler’s A604 transaxle assembly that points out important

locations a technican would need to inspect before replacing a suspect leaky solenoid block

assembly. So, before you perform service on the Chrysler A604 solenoid block assembly

because of a leak, you may want to inspect the surrounding components to ensure that the leak

is not from the below illustrated components. (See Reverse Side For Solenoid Installation)

Installation Instructions

1998 and Earlier Models

When installing the ATP TE-6 solenoid on 1998 and earlier model A604 transaxles, the

alignment dowel pins may have to be repositioned to allow proper fitment of the

solenoid body to the transaxle case.

Some earlier transmission case bolts are counter-bored and will only allow the dowel

pins to penetrate about .125” inside the case. To properly install the TE-6 solenoid on

earlier A604 transaxles, the (2) dowel pins must be lightly tapped down with a hammer

to allow the dowel pins to protrude .125” from the solenoid assembly.

Do not reuse the old gasket and spacer plate. Use only the supplied gasket when

installing. The old gasket and spacer plate do not interchange with the TE-6 solenoid.

Mismatching the gasket or using the old gasket and spacer plate can cause serious

pressure leaks and unit malfunctions.

Form No. REV.TE6.0611